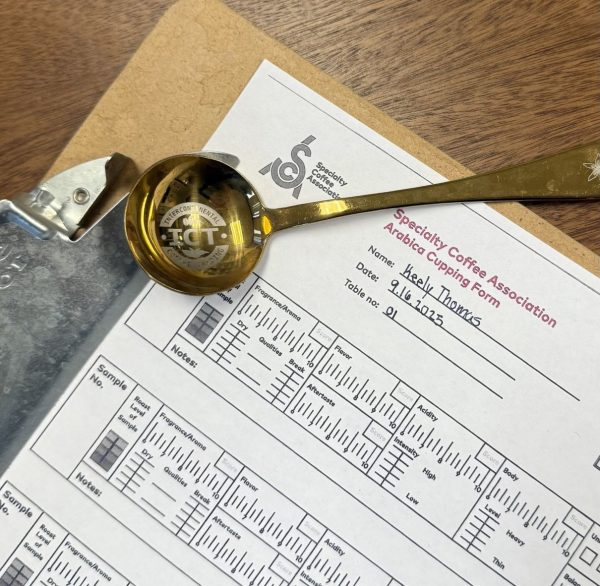

As green coffee importers, we at ICT see firsthand how proper cupping protocols protect your investment and ensure customer satisfaction. Whether you’re a new roaster or expanding your quality control systems, understanding cupping’s role in the supply chain will directly impact your bottom line.

The Foundation: What Makes Cupping Essential

Cupping isn’t just coffee tasting; it’s your quality insurance policy. Every bag of coffee you purchase represents a significant investment, and cupping is the only way to verify you’re getting what you paid for.

Without systematic cupping, you’re buying coffee blind. With it, you have documented proof of quality at every stage of your supply chain.

The Standard Protocol: Why Consistency Matters

The Specialty Coffee Association’s cupping protocol exists for one reason: fair comparison. When everyone uses the same method, you can trust the results.

The SCA cupping recipe:

- 8.25g coffee per 150ml water

- Medium-coarse grind (850-900 microns)

- Water at 200°F (93°C)

- 4-minute steep before breaking crust

Why these numbers matter: They create laboratory conditions that reveal coffee’s true character. Change any variable, and you’re no longer comparing apples to apples.

Your Supply Chain Protection: Four Critical Cupping Stages

1. Offer Sample Cupping (Before You Buy)

- What we do: Comprehensive evaluation of samples before you commit to purchase

- What you get: Detailed cupping notes and quality scores that inform your buying decisions

- Your benefit: No surprises when your coffee arrives – you know exactly what you’re getting

2. Pre-Shipment Cupping (Before Export)

- What we do: Quality verification that coffee leaving origin matches your purchase

- What you get: Confirmation that your contracted coffee maintains expected quality

- Your benefit: Protection against quality drops during processing or storage at origin

3. Arrival Cupping (When Coffee Reaches Our Warehouse)

- What we do: Quality check after international shipping

- What you get: Documentation that your coffee survived transit without quality loss

- Your benefit: Immediate notification if shipping affected your coffee’s quality

4. Inventory Monitoring (During Storage)

- What we do: Regular quality spot-checks of stored coffee

- What you get: Updates on how your coffee ages and optimal release timing

- Your benefit: Strategic inventory management based on actual quality data

What This Means for Your Roasting Business

Immediate Benefits

- Every coffee comes with documented quality verification

- Multiple quality checkpoints protect your investment

Long-Term Advantages

- Customer Consistency: Quality control ensures your customers get the same great coffee every time, building loyalty and repeat business.

- Profit Protection: Early defect detection prevents costly quality issues from reaching your customers or forcing expensive product replacements.

- Supplier Relationships: Quality documentation creates productive conversations with producers and suppliers, backed by concrete data.

Your Role: Implementing Cupping at Roaster Level

Even with comprehensive import-level cupping, roaster-level evaluation remains essential for optimal results.

Essential Roaster Cupping Practices

- Arrival Confirmation: Cup every new coffee arrival to verify it matches our documentation and your expectations.

- Aging Assessment: Regular cupping tracks how your stored coffee changes over time, guiding inventory rotation decisions.

- Roast Development: Systematic cupping of roast trials ensures you maximize each coffee’s potential.

- Team Calibration: Regular team cupping sessions build consistent evaluation skills and shared flavor vocabulary.

The ICT Advantage: Comprehensive Quality Documentation

Our cupping program provides you with complete quality transparency throughout the supply chain.

Our comprehensive documentation includes detailed cupping notes that cover every aspect of sensory evaluation, from fragrance and aroma to taste, acidity, body, balance, and overall quality assessment. We provide numerical quality scores that enable objective comparison between different coffees and lots, removing guesswork from your purchasing decisions. Our time-series aging data helps you predict optimal usage windows for inventory management, while our systematic defect identification serves as an early warning system for any quality concerns that require immediate attention.

Building Your Cupping Program:

Start Simple

Begin with basic arrival confirmation cupping using SCA protocols. This single step provides immediate quality verification and ROI.

Expand Systematically

Add regular inventory monitoring once arrival cupping becomes routine. This builds valuable aging data for inventory management.

Develop Team Skills

Schedule regular team cupping sessions to build consistent evaluation capabilities across your staff.

Document Everything

Keep detailed cupping records that track quality over time and support strategic decision-making.

Quality Assurance You Can Count On

Working with ICT means partnering with importers who understand that your success depends on consistent coffee quality. Our comprehensive cupping program provides quality documentation and supply chain transparency that supports confident purchasing decisions and successful coffee programs.

Our commitment: Every coffee we import undergoes systematic quality evaluation at multiple stages, providing you with detailed quality information that supports optimal coffee utilization and customer satisfaction.

Your advantage: Access to exceptional coffee backed by comprehensive quality documentation, enabling strategic sourcing decisions based on verified quality information rather than guesswork.

The Competitive Edge

In today’s competitive coffee market, consistent quality separates successful roasters from the rest. Systematic cupping – both at import and roaster level – creates the quality foundation that enables business growth and customer loyalty.

The reality: Customers notice quality consistency. Cupping protocols ensure you deliver that consistency while maximizing each coffee’s potential and protecting your investment.

The opportunity: Partner with importers who prioritize quality documentation and implement systematic cupping at your facility to build competitive advantages through superior quality control.